We are living in a society, where the science and technology have taken the center stage of all possible developments and in almost every day, we are witnessing some new concepts or developments in the arena of the science and technology that helps our life and circumstances to be more composed and ease. Very recently some scientists and engineers have developed a method that can be of great help for materials, especially Supercritical carbon dioxide, for various applications, ranging from batteries to the most elegant biosensors1. Some of the relevant issues, related to these developments are as follows:

- Sreenivasa Reddy Puniredd and his colleagues of an “A” Star Material Research and Engineering institute have developed a simple and new way that can be helpful to deliver the essential protective molecules by using the Supercritical carbon dioxide, popularly known as scCO2.

- In this process, the normal Carbon Dioxide is being converted to the Supercritical carbon dioxide under extremely high pressure, when this becomes the free-flowing liquid, which is chemically inexpensive, inert and comparatively more environment-friendly than other traditional solvents.

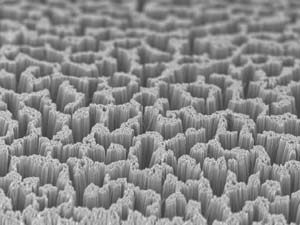

- The research team used the Supercritical carbon dioxide, scCO2, in carrying molecules, known as alkyl thiols, which is having a long chain of carbons and an atom of Sulfur at one of the end. Here Sulfur forms the stable bond with the silicon, while water-repelling chains of carbons make the tightly-packed skin on the surface of the silicon.

- This is a simple green method, where the silicon forms the oxide layer on the surface at the time of exposure to moisture and air, which have the potential to detract from its own electronic properties. It can be noted that the adding of the molecular “skin” to the silicon is providing a physical barrier to prevent oxidation, but by forming these monolayers could have been tricky and require longer processing time, as well as, the inert atmosphere or demanding the uses of the harmful solvents of organic nature.

- In applying the coating, researchers had used alkyl thiols that contain seven to eighteen atoms that could coat germanium, silicon and the silicon nanowires. Each of the procedures took almost few hours and able to produce monolayers of 1.6 nanometers to 2.3 nanometers of thickness, which are able to resist wear and in repelling water to a great extent. The most notable and greatest effect had been seen for the longest chains of alkyl thiols.

- These monolayers also having the potential of protecting the surface, more than fifty days, from oxygen. These are prepared by using the conventional solvents, had been typically stable for the shorter period of time, even less than one week. It is stated that the increase in the stability was an expected issue, but such a longer stability was a real surprise for the research team.

- Ths Supercritical carbon dioxide technology can be used in the modification of a different variety of inorganic surface and it may be worth mentioning that this technology is able to enhance the stability and enhancement of the respective film, apart from being scalable.